High Specific Gravity Tungsten Alloy

High Specific Gravity Tungsten Alloy

Lub ntiajteb txawj nqus tshwj xeeb tungsten alloy yog raws li tungsten, nrog me me ntawm Ni, Co, Mo, thiab lwm yam ntxiv rau nws. Nws yog ib tug raug ob-theem alloy thiab tseem hu ua "high-density alloy".

Raws li cov khoom siv sib txawv thiab kev ua haujlwm ib puag ncig, tungsten cov ntsiab lus ntawm cov khoom sib nqus tshwj xeeb tungsten alloy feem ntau yog 79% W ~ 97% W, thiab qhov ceev yog 15.00g / cm³ ~ 18.50g / cm³. Nyob rau tib lub sijhawm, qee cov hlau tsis tshua muaj (Co, Mo, Cr, thiab lwm yam) tuaj yeem muab ntxiv los txhim kho qee yam khoom ntawm cov khoom, xws li hardness, qhov kawg tensile zog, yield zog elongation, thiab lwm yam.

High-specific gravity tungsten alloys feem ntau muab faib ua ob pawg, tungsten-nickel-copper alloy (W-Ni-Cu) thiab tungsten-nickel-hlau alloy (W-Ni-Fe).

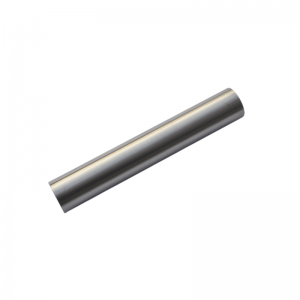

Peb muab cov khoom sib nqus tshwj xeeb tungsten alloy cov khoom, suav nrog cov pas nrig, daim hlau, cov khoom ua tiav, thiab lwm yam. Peb muaj cov tshuab laser txiav, CNC ua cov cuab yeej, grinders, hlau-txiav tshuab, thiab lwm yam khoom siv los muab koj ntau yam precision. kev pabcuam.

Daim ntawv thov ntawm High Specific Gravity Tungsten Alloy

•Aerospace gyroscope rotors, counterweights, shock absorbers.

•Armor-piercing cores rau cov pa riam phom.

•Radiation shielding thiab cov khoom.

•Tuag-casting pwm, flywheels thiab tsis siv neeg saib pendulums rau machinery manufacturing.

•Tiv tauj thiab electrodes ntawm cov khoom siv hluav taws xob, thiab lwm yam.

Lub cev khoom

| W (%) | Qhov ceev (g / cm3) | Hardness (HRC) | Tensile zog (MPa) | Elongation (%) |

| 90 | 16.85-17.25 dr hab | 24-32 : kuv | 700-1200 (600-800) hli | 20-33(4-8) hnub. |

| 92.5 ib | 17.15-17.85 dr hab | 25-30 | 700-1400 (500-600) hli | 15-25 (3-5) hnub |

| 95 | 17.75-18.35 dr hab | 25-35 : kuv | 700-1200 Nws | 8-15 |

| 97 | 18.25-18.85 dr hab | 30-35 : kuv | 600-1000 | 8–14 |

Lub sintering ntawm lub ntiajteb txawj nqus tshwj xeeb tungsten alloy yog qhov txuas tseem ceeb heev. Cov txheej txheem sintering muaj qhov cuam tshuam zoo rau qhov ntom, qhov loj me, kev sib cais, thiab microstructure ntawm cov hlau. Peb nruj me ntsis tswj txhua txoj kev tsim khoom kom ntseeg tau tias peb cov khoom zoo.

Koj puas xav paub ntau ntxiv txog peb cov khoom?

Hu rau kuv

Amanda│Tus Thawj Tswj Muag

E-mail: amanda@winnersmetals.com

Xov tooj: +86 156 1977 8518 (WhatsApp/Wechat)

Yog tias koj xav tau cov ntsiab lus ntxiv thiab tus nqi ntawm peb cov khoom, thov hu rau peb tus neeg muag khoom, nws yuav teb sai li sai tau (feem ntau tsis pub dhau 24 teev), ua tsaug.