Molybdenum crucible rau electron beam evaporation

Product Description

Kub kub resistant hlau

Tej zaum koj yuav muaj cov teeb meem no: qhov kub thiab txias yog siab dhau, lub thawv hlau zoo tib yam tsis tuaj yeem dais nws, lossis lub thawv ntim tau yooj yim, thiab lwm yam, ces kuv xav tias koj tuaj yeem sim cov hlau resistant kub, "molybdenum".

Qhov ceev ntawm molybdenum yog 10.2g / cm³, lub melting point yog 2610 ℃, thiab boiling point yog 5560 ℃.Molybdenum yog cov hlau dawb-dawb, tawv thiab tawv, nrog lub siab melting point, siab thermal conductivity, thiab corrosion kuj.

Qhov kev siv kub ntawm cov ntshiab molybdenum crucible feem ntau yog 1100 ℃ ~ 1700 ℃.Thaum siv hauv lub tshuab nqus tsev, nws tuaj yeem tiv taus qhov kub thiab txias thiab tiv thaiv kom tsis txhob muaj kab mob ntawm cov txheej thaum txheej txheej.

Khoom parameters

| Cov khoom npe | Molybdenum crucibles |

| Purity | 99.95% |

| Qhov ntom | 10.2g / cm3 |

| MOQ | 1 qob |

| Muaj peev xwm | 3ml :ua50ml los yog raws li koj xav tau |

| Max ua haujlwm kub | 1700 ℃ |

| Txheej txheem ntau lawm | Machined-Polishing |

Qhov zoo

■ Tsis muaj kuab paug, lub neej ua haujlwm ntev.

■ Muaj peev xwm hloov cov ntaub ntawv sai.

■ Txhim kho tus nqi evaporation, luv lub sij hawm voj voog thiab nce ntau lawm.

Molybdenum crucibles feem ntau yog siv rau:

■Optical txheej■Electron beam evaporation txheej■Rau kev tshawb fawb

Crucibles Selection Table

Txawm hais tias ntshiab molybdenum crucible yog ib qho kev xaiv zoo, muaj ntau yam khoom siv evaporative, thiab tsis yog txhua yam khoom tsim nyog.Raws li kev paub dhau los, peb muaj lub rooj xaiv yooj yim rau koj siv.

| Evaporator | Crucible khoom | ||

|

| W | Mo | Ta |

| Aluminium |

| √ | √ |

| Alumina Al2O3 |

| √ | √ |

| Beryllium | √ | √ | √ |

| Gallium | √ | √ | √ |

| Kub |

| √ | √ |

| Coj | √ | √ | √ |

| Hlau | √ | √ | √ |

| Platinum | √ | √ | √ |

| Evaporator | Crucible khoom | ||

|

| W | Mo | Ta |

| Silicon | √ | √ |

|

| Nyiaj | √ |

| √ |

| Titanium |

| √ | √ |

| Magnesium | √ | √ | √ |

| Titanium Dioxide | √ | √ |

|

| Zirconium |

| √ | √ |

| Zirconium Oxide |

| √ | √ |

Peb qhov zoo

Xaiv cov hmoov zoo molybdenum los xyuas kom meej purity

Kev tshaj lij kev tsim khoom, cov khoom lag luam yog qhov loj me, ci ntsa iab

Tsim nyog thev naus laus zis, lub sijhawm luv luv thiab tus nqi nyiam

Customized raws li cov duab kos, txawm tias 1 daim tuaj yeem ua tau

Cov ntaub ntawv xaj

Kev nug thiab kev txiav txim yuav tsum muaj cov ntaub ntawv hauv qab no:

✔Khoom siv (Tungsten, Molybdenum, Tantalum, Tooj)

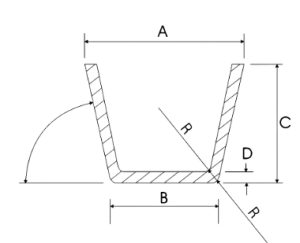

✔Kev kos duab ntawm lub crucibles, yog tias tsis muaj kev kos duab, qhia rau peb txog cov kab uas hla, phab ntsa thickness, tus tim tswv thiab qhov siab.

✔Ntau

Yog tias koj xav paub ntau ntxiv txog cov khoom, thov hu rau peb, peb tus neeg muag khoom thiab tus engineer yuav teb koj li ntawm 24 teev.

Hais txog peb

Qhov tseeb, peb yog cov chaw tsim khoom hauv Suav teb, peb tus kheej tsim thiab ua cov ntaub ntawv raw ntawm tungsten, molybdenum, tantalum, niobium thiab titanium thiab lawv cov khoom ua tiav.

Cov khoom lag luam feem ntau suav nrog kev lag luam:

■Kub kub lub tshuab nqus tsev rauv rauv tungsten thiab molybdenum accessories thiab consumables.

■Tungsten, molybdenum thiab tantalum crucibles, tungsten xov hlau thiab cua sov xov hlau rau lub tshuab nqus tsev.

■Tungsten thiab molybdenum accessories thiab consumables rau ion implanters nyob rau hauv lub semiconductor kev lag luam.

■Tungsten thiab molybdenum accessories thiab consumables rau ib leeg siv lead ua rub rauv hauv kev lag luam photovoltaic.

■CNC machining ntawm lwm cov ntaub ntawv hlau xws li tungsten, molybdenum, tantalum, niobium, thiab titanium.

Peb ib txwm coj cov khoom "zoo" raws li peb lub hauv paus.Thiab peb zoo siab los pab cov neeg siv khoom txo cov nqi tsim nyog thiab daws teeb meem ntsib.