Molybdenum Crucibles rau E-Beam Sources

Molybdenum E-Beam Crucibles

Ntshiab Molybdenum (Mo) liners yog siv rau electron beam evaporation txheej, thiab qhov siv tau kub tuaj yeem ncav cuag 1800 ° C.Nws tiv taus qhov kub thiab txias thiab corrosion, thiab tuaj yeem tiv thaiv kom muaj kuab paug ntawm cov txheej txheem thaum txheej txheej txheej txheej.

Peb muab 4cc, 7cc, 15cc, 25cc, 30cc, 40cc, 100cc thiab lwm qhov ntau thiab tsawg (customizable) ntshiab molybdenum crucible liners.Nws yog qhov tsim nyog rau cov khoom siv hluav taws xob feem ntau, tsis hais seb koj lub tshuab hluav taws xob hluav taws xob qhov dej txias yog ib lub hnab tshos lossis ntau lub hnab ris, nws tuaj yeem ntsia tau thiab siv tau ib txwm.

Peb cov molybdenum crucible liners feature siab purity, high-temperature kuj, thiab zoo heev creep thiab corrosion kuj.Yog li ntawd, lub sij hawm evaporation yuav luv luv, kev pab cuam lub neej yuav ntev, thiab cov nqi ntau lawm yuav txuag tau.

Molybdenum Crucible Cov ntaub ntawv

| Khoom npe | Molybdenum (Mo) Crucibles |

| Purity | 99.95% |

| Qhov ntom | 10.2g / cm3 |

| Melting Point | 2620 ℃ |

| Ua haujlwm kub | 1100 ℃ - 1800 ℃ |

| Txheej txheem ntau lawm | Machined-Polishing |

| Daim ntawv thov | E-Beam Evaporation, Lab siv |

| Hom | 4cc, 7cc, 15cc, 25cc, 30cc, 40cc, 100cc, tuaj yeem kho |

| MOQ | 2 qab |

Daim ntawv thov

Molybdenum (Mo) crucible liner yog siv rau:

•Evaporation Txheej

•Electron Beam Txheej

•Lab siv

Peb cov khoom siv crucible yog tsim rau feem ntau cov khoom siv hluav taws xob hluav taws xob evaporation, txawm tias nws yog ib lub hnab tshos crucible puag lossis ntau lub hnab tshos, nws tuaj yeem haum.

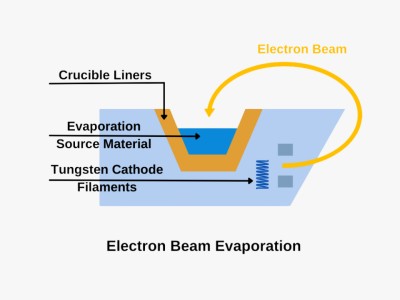

Hais txog Electron Beam Evaporation Txheej

Cov txheej txheem electron beam evaporation yog ib hom ntawm lub tshuab nqus tsev evaporation txheej, uas siv cov kab hluav taws xob hluav taws xob ncaj qha rau cov khoom evaporation nyob rau hauv lub tshuab nqus tsev, vaporize cov khoom evaporation thiab thauj mus rau lub substrate, thiab condense ntawm lub substrate los ua ib tug nyias zaj duab xis.

Electron beam evaporation tuaj yeem evaporate siab melting point cov ntaub ntawv, uas muaj ntau dua thermal efficiency, siab dua beam tam sim no ceev thiab evaporation sai dua li cov cua sov evaporation.Cov yeeb yaj kiab nyias nyias muaj cov purity siab thiab zoo zoo, tuaj yeem tswj cov thickness ntau dua, thiab tuaj yeem siv dav hauv kev npaj ntau yam khoom siv kho qhov muag nyias zaj duab xis xws li high-purity nyias films thiab conductive iav.

Molybdenum E-Beam Crucible Loj

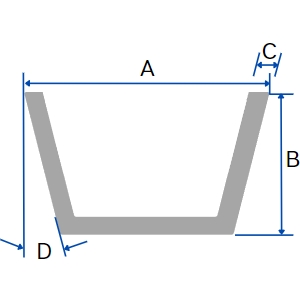

Daim duab piav qhia:

1. Thaum cov khoom tsis muab cov duab kos, nws yuav ua tiav raws li daim duab kos thiab qhov loj ntawm cov lus hauv qab no los ntawm lub neej ntawd.

2. Cov npoo thiab cov ces kaum ntawm cov khoom yog chamfered (C0.5 ~ C1) los ntawm lub neej ntawd, thov piav qhia seb lwm qhov ntau thiab tsawg lossis R cov ces kaum siv.

3. Ua ntej cov khoom tiav, yog tias tsis muaj cov duab kos, peb lub tuam txhab yuav muab cov duab kos dawb rau koj qhov kev pom zoo.

| Ntim | Sab saum toj Dia (A) × Qhov siab (B) × Phab ntsa thickness (C) |

| 4cc ua | 0.88 nti (22.4mm) × 0.59 nti (14.9mm) × 0.093 nti (2.36mm) |

| 7cc ib | 1.12 nti (28.5mm) × 0.51 nti (12.9mm) × 0.093 nti (2.36mm) |

| 15cc ua | 1.49 nti (37.8mm) × 0.68 nti (17.3mm) × 0.125 nti (3.17mm) |

| 25cc loj | 1.85 nti (47.0mm) × 0.69 nti (17.5mm) × 0.125 nti (3.17mm) |

| 25cc tob | 1.63 nti (41.4mm) × 0.93 nti (23.6mm) × 0.125 nti (3.17mm) |

| 30cc nrog web | 1.92 nti (48.8mm) × 0.95 nti (24.1mm) × 0.125 nti (3.17mm) |

| 30cc tsis web | 1.80 nti (45.7mm) × 0.80 nti (20.3mm) × 0.125 nti (3.17mm) |

| 40cc ua | 2.03 nti (51.6mm) × 1.03 nti (26.2mm) × 0.125 nti (3.17mm) |

| 100cc ua | 2.80 nti (71.1mm) × 1.50 nti (38.1mm) × 0.125 nti (3.17mm) |

| Txhua lub kaum sab xis (D) yog 15 °, Txhua qhov kev qhia tshwj xeeb tuaj yeem ua raws li daim duab kos. | |

Peb Qhov Zoo

•Xaiv cov hmoov zoo molybdenum los xyuas kom meej purity.

•Kev tshaj lij kev tsim khoom, cov khoom lag luam yog qhov loj me, ci ntsa iab.

•Tsim nyog thev naus laus zis, lub sijhawm luv luv thiab tus nqi nyiam.

•Customized raws li cov duab kos, txawm tias 2 daim tuaj yeem ua tau.

Nrog ntau tshaj kaum xyoo kev paub ntawm kev lag luam, peb tuaj yeem tsim cov molybdenum crucailes nrog lub qhov ntev heev thiab kev ua kom zoo nkauj, lub siab du thiab corrosion tsis kam.

Peb cov crucibles tau siv los ntawm ntau tus neeg siv khoom thoob ntiaj teb nrog kev ua tiav zoo.Txawm hais tias nws yog ib qho me me rau kev sim siv (10mm txoj kab uas hla) lossis loj crucible rau kev lag luam siv (300mm txoj kab uas hla), peb tuaj yeem tsim nws.

Peb muab evaporation qhov chaw thiab evaporation cov ntaub ntawv rau PVD txheej & Optical txheej, cov khoom no muaj xws li:

| Electron Beam Crucible Liners | Tungsten Coil rhaub | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Cov khoom siv evaporation | Nkoj Evaporation |

Tsis muaj cov khoom koj xav tau?Thov hu rau peb, peb yuav daws nws rau koj.

Koj puas xav paub ntau ntxiv txog peb cov khoom?

Hu rau kuv

Amanda│Tus Thawj Tswj Muag

E-mail: amanda@winnersmetals.com

Xov tooj: 0086 156 1977 8518 (WhatsApp/Wechat)

Yog tias koj xav paub ntau ntxiv thiab cov nqi ntawm peb cov khoom, thov hu rau peb tus neeg muag khoom, nws yuav teb koj sai li sai tau (feem ntau tsis pub dhau 24 teev), ua tsaug.