Molybdenum Boats rau Thermal Evaporation

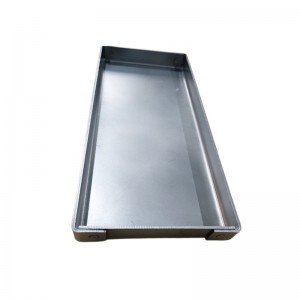

Molybdenum (Mo) Nkoj

Molybdenum tej nkoj nquam yog cov khoom tseem ceeb uas siv rau hauv cov txheej txheem ntawm lub cev vapor deposition (PVD), tshwj xeeb tshaj yog cov txheej txheem thermal evaporation. Cov nkoj no ua haujlwm li crucibles lossis cov nkoj kom muaj thiab evaporate cov khoom siv, cia cov yeeb yaj kiab nyias tso rau hauv substrates.

Molybdenum tej nkoj nquam siv nyob rau hauv cov txheej txheem thermal evaporation tuaj yeem raug cais raws li ntau yam, suav nrog lawv cov duab, qhov loj me, thiab cov ntawv thov tshwj xeeb. Cov hauv qab no yog kev faib tawm ntawm cov nkoj molybdenum:

• Raws li cov duab sib txawv, cov nkoj molybdenum yog puag ncig, duab plaub, square thiab trapezoidal;

• Raws li kev ua haujlwm sib txawv, cov nkoj molybdenum tuaj yeem muab faib ua cov nkoj thwj, folding nkoj, vuam nkoj, thiab cov nkoj riveting;

• Raws li cov ntaub ntawv sib txawv, nws tuaj yeem muab faib ua cov nkoj ntshiab molybdenum, molybdenum-lanthanum nkoj, molybdenum-zirconium-titanium nkoj, molybdenum-rhenium nkoj, tungsten-molybdenum nkoj, thiab lwm yam.

Molybdenum (Mo) Nkoj

| Cov khoom npe | Molybdenum Boats |

| Khoom siv | Mo1, Muas |

| Qhov ntom | 10.2g / cm³ |

| Purity | ≥99.95% |

| Technology | Riveting, Stamping, thiab lwm yam. |

| Daim ntawv thov | Nqus Metallization |

Qhov zoo ntawm Molybdenum Boat

Lub nkoj molybdenum yog ib qho tseem ceeb ntawm cov txheej txheem thermal evaporation hauv kev siv lub tshuab nqus tsev. Qee qhov txiaj ntsig tseem ceeb ntawm nws muaj xws li:

• Kub-kub stability

• Cov cua kub sib xws thiab vaporization

• Chemically inert

• Tsim versatility

• Compatibility nrog lub tshuab nqus tsev ib puag ncig

• Durability thiab ntev

• Ntau yam kev siv

Daim ntawv thov

Molybdenum nkoj muaj ntau yam kev siv hauv kev lag luam uas siv cov txheej txheem thermal evaporation rau nyias zaj duab xis deposition. Qee qhov kev siv feem ntau suav nrog kev tsim khoom semiconductor, optics thiab photonics, kev hloov kho qhov chaw thiab cov txheej txheem ua haujlwm, kev tshawb fawb thiab kev loj hlob ntawm cov yeeb yaj kiab, cov ntaub ntawv tshawb fawb thiab engineering, hnub ci cell thiab photovoltaic kev lag luam, kho kom zoo nkauj thiab ua haujlwm txheej, thiab lwm yam.

Molybdenum Boat Shape Xaiv

| Pav ca zawj molybdenum nkoj | Haum rau cov ntaub ntawv siab wettability. |

| V-shaped zawj molybdenum nkoj | Haum rau cov ntaub ntawv uas muaj tsawg wettability. |

| Oval grooved molybdenum nkoj | Haum rau cov khoom siv hauv lub xeev molten. |

| Spherical zawj molybdenum nkoj | Haum rau cov khoom kim heev xws li kub thiab nyiaj. |

| Nqaim qhov molybdenum nkoj | Qhov kev tsim no tiv thaiv cov khoom vapor deposition los ntawm lo rau cov filament clip. |

Nrov Loj

| Qauv | Thickness (hli) | Dav (mm) | Ntev (mm) |

| #210 | 0.2 | 10 | 100 |

| #215 | 0.2 | 15 | 100 |

| #220 | 0.2 | 20 | 100 |

| #310 | 0.3 | 10 | 100 |

| #315 | 0.3 | 15 | 100 |

| #320 | 0.3 | 20 | 100 |

| #510 | 0.5 | 10 | 100 |

| #515 | 0.5 | 15 | 100 |

| Nco tseg: Cov kev qhia tshwj xeeb thiab qhov ntev tuaj yeem ua tiav raws li cov duab kos lossis cov qauv. | |||

Peb muab evaporation qhov chaw thiab evaporation cov ntaub ntawv rau PVD txheej & Optical txheej, cov khoom no muaj xws li:

| Electron Beam Crucible Liners | Tungsten Coil rhaub | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Cov khoom siv evaporation | Nkoj Evaporation |

Tsis muaj cov khoom koj xav tau? Thov hu rau peb, peb yuav daws nws rau koj.

Koj puas xav paub ntau ntxiv txog peb cov khoom?

Tiv tauj peb

Amanda│Tus Thawj Tswj Muag

E-mail: amanda@winnersmetals.com

Xov tooj: +86 156 1977 8518 (WhatsApp/Wechat)

Yog tias koj xav paub ntau ntxiv thiab cov nqi ntawm peb cov khoom, thov hu rau peb tus neeg muag khoom, nws yuav teb koj sai li sai tau (feem ntau tsis pub dhau 24 teev), ua tsaug.