TZM alloy tam sim no yog cov khoom siv kub siab zoo tshaj plaws ntawm molybdenum alloy. Nws yog cov khoom siv khov kho thiab cov khoom siv molybdenum-based alloy uas tau ua los ntawm cov khoom siv khov kho, TZM nyuaj dua li cov hlau molybdenum ntshiab, thiab muaj qhov kub recrystallization siab dua thiab tiv taus creep zoo dua, qhov kub recrystallization yog li 1400 ° C, siab dua rau molybdenum, nws tuaj yeem muab kev sib txuas zoo dua.

MHC yog ib qho hlau molybdenum uas muaj cov khoom me me uas muaj hafnium thiab carbon. Vim yog qhov sib faib ua ke ntawm cov carbides zoo heev, cov khoom siv tseem muaj qhov zoo ntawm kev tiv taus cua sov zoo heev thiab kev tiv taus nkag ntawm qhov kub ntawm 1550 ° C, thiab qhov kub siab tshaj plaws uas pom zoo kuj yog 150 ° C siab dua li ntawm TZM. Piv txwv li hauv cov pwm extrusion, nws tuaj yeem tiv taus cov cua sov thiab cov khoom siv kho tshuab hnyav, yog li cov ntaub ntawv MHC raug pom zoo rau kev siv hlau.

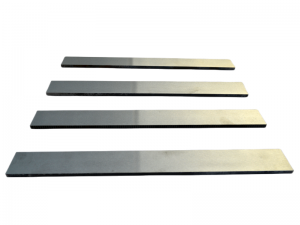

Molybdenum-zirconium alloy, doped nrog me me ntawm zirconia (ZrO2) hauv molybdenum ntshiab, tuaj yeem txhim kho qhov corrosion tsis kam thiab creep tsis kam ntawm molybdenum.

Ntxiv cov khoom tsis tshua muaj hauv ntiaj teb tsis tsuas yog txhim kho qhov kub recrystallization thiab qhov kub siab creep tsis kam ntawm molybdenum, tab sis kuj tseem txo qhov kub hloov pauv ntawm yas-brittle ntawm molybdenum, ua rau ductility, thiab txhim kho qhov kub hauv chav brittleness thiab qhov kub siab sag tsis kam ntawm molybdenum.

Daim Ntawv Thov

Vim nws muaj zog kub zoo heev, kub recrystallization siab thiab thermal conductivity zoo, TZM alloy yog siv dav hauv aerospace, aviation thiab lwm yam teb, xws li cov khoom siv nozzle, cov khoom siv nozzle, lub cev roj valve, cov yeeb nkab roj. Nws kuj tseem siv tau ua X-ray rotating anode qhov chaw, die-casting pwm thiab extrusion pwm, cov khoom cua sov thiab cov ntaub thaiv cua sov hauv cov cub tawg kub siab.

MHC alloys yog dav siv rau hauv cov hlau tsim daim ntawv thov:

● Cov hlau molybdenum uas tsis tshua muaj neeg siv feem ntau yog siv ua cov xov hluav taws xob, EDM electrode thiab cov khoom siv cua sov kub heev.

● Cov phaj thiab cov ntawv molybdenum uas tsis tshua muaj neeg siv yog siv ua cov wafers rau kev luam rau hauv thyristors, nrog rau cov ntaub thaiv cua sov thiab cov ntawv qhia rau cov raj hluav taws xob.

● Cov hlau molybdenum uas tsis tshua muaj neeg siv tau ua lub taub hau hlau kub zoo, nrog rau cov khoom siv hauv kev lag luam aerospace thiab nuclear, cov hom phiaj X-ray, cov pwm die-casting thiab cov pwm extrusion.

● Cov khoom zoo li molybdenum uas tsis tshua muaj neeg siv yog siv ua cov electrodes iav yaj, cov electrodes smelting tsis tshua muaj neeg, crucibles, cov nkoj sintering kub siab, cov ntaub thaiv cua sov kub siab, cov qhov dej ntws, cov rails qhia, cov pads, thiab lwm yam.

● Cov hlau molybdenum uas tsis tshua muaj neeg siv kuj siv tau ua cov khoom siv cathode kub rau cov raj hluav taws xob nruab nrab thiab siab. Cov khoom siv cathode thermal cathode uas tsis tshua muaj neeg siv hloov cov cathode tungsten tam sim no, uas muaj qhov kub ua haujlwm siab, muaj kuab paug radioactive, thiab brittleness siab, thiab tuaj yeem txo qhov kub ua haujlwm ntawm lub raj thiab txhim kho kev ntseeg siab.

Baoji Winners tsim cov khoom siv tungsten thiab molybdenum thiab nws cov khoom siv alloy thiab tuaj yeem hloov kho kom tau raws li cov neeg siv khoom xav tau. Yog xav paub ntxiv txog cov khoom lag luam, thov hu rau peb (Whatsapp: +86 156 1977 8518).

Lub sijhawm tshaj tawm: Lub Yim Hli-02-2022