Tungsten stranded hlau yog ib yam khoom siv rau lub tshuab nqus tsev, uas feem ntau yog tsim los ntawm ib leeg lossis ntau cov doped tungsten xov hlau nyob rau hauv ntau yam duab ntawm cov khoom hlau. Los ntawm cov txheej txheem kev kho cua sov tshwj xeeb, nws muaj zog tiv thaiv corrosion thiab kub kub ua haujlwm, zoo stability thiab kev pab lub neej ntev. Nws yog tam sim no dav siv nyob rau hauv lub tshuab nqus tsev txheej txheej ntawm nyias zaj duab xis tshuab, hlau evaporation, daim iav kev lag luam, txhuas thiab lwm yam khoom dai kom zoo nkauj, chrome plating, thiab lwm yam.

Kev tsim cov txheej txheem ntawm tungsten stranded hlau

1. Kev kos duab: siv lub tshuab nqus hlau thiab rov qab kos cov tungsten puag ncig tus pas nrig rau qhov loj me, xws li Φ1.0mm, Φ0.8mm, Φ0.76mm, Φ0.6mm

2. Alkaline tu lossis electropolishing: lub tungsten hlau tom qab ntxuav alkali yog dawb, thiab tungsten hlau tom qab electropolishing muaj xim hlau luster.

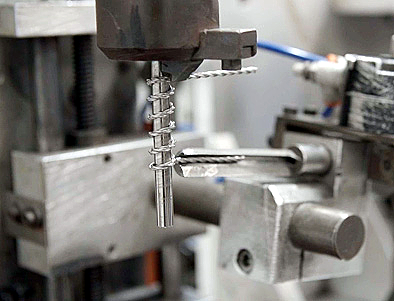

3. Cov khoom sib koom ua ke: Twist lub tungsten hlau rau hauv 2 strands, 3 strands, 4 strands los yog ntau tshaj nrog lub tshuab plying, thiab cov tungsten strands yog npaj rau kev siv.

4. Moulding: Siv tungsten strand forming tshuab los ua tungsten hlau rau hauv ntau yam duab ntawm tungsten strand.

5. Kev tshuaj xyuas thiab kev khaws cia: Siv cov cuab yeej tshaj lij los kuaj xyuas qhov pom thiab ntsuas qhov ntev, thiab lwm yam, thiab sau npe cov khoom tsim nyog rau kev khaws cia.

Lub hauv paus ntsiab lus ua haujlwm ntawm tungsten stranded hlau

Tungsten muaj cov ntsiab lus siab melting, siab resistivity, tsis tshua muaj vapor siab thiab siab zog, thiab yog haum rau evaporators.Cov khoom siv lub hom phiaj yog muab tso rau hauv lub tungsten stranded hlau nyob rau hauv lub tshuab nqus tsev chamber. Nyob rau hauv lub tshuab nqus tsev siab, lub tungsten stranded hlau yog rhuab kom evaporate nws. Thaum txoj kev tsis pub dawb ntawm cov evaporated molecules ntau dua li qhov linear loj ntawm lub tshuab nqus tsev, cov atoms thiab molecules ntawm vapors raug tshem tawm ntawm qhov chaw evaporation. Tom qab qhov chaw khiav tawm, nws tsis tshua muaj kev cuam tshuam thiab cuam tshuam los ntawm lwm cov molecules lossis atoms, thiab tuaj yeem ncaj qha mus txog saum npoo ntawm substrate kom plated. Vim qhov kub ntawm cov substrate qis, nws condenses los ua ib zaj duab xis nyias.

Hais txog peb

Baoji Winners Hlau yog cov chaw tsim khoom ntawm tungsten, molybdenum, tantalum thiab niobium cov khoom siv. Lub tuam txhab cov khoom tseem ceeb yog: tungsten, molybdenum, tantalum, thiab niobium crucibles, tungsten strands rau txheej, tungsten thiab molybdenum screws / bolts, ion cog tungsten thiab molybdenum workpieces, thiab lwm yam tungsten, molybdenum cov khoom, Cov khoom no tsuas yog siv rau hauv qhov cub kub kub, semiconductor ion implantation, photovoltaic ib leeg siv lead ua rauv, PVD txheej thiab lwm yam lag luam. Yog tias tsim nyog, thov hu rau peb: +86 156 1977 8518 (Whatsapp)

Post lub sij hawm: Sep-21-2022