Tungsten Boats rau Thermal Evaporation

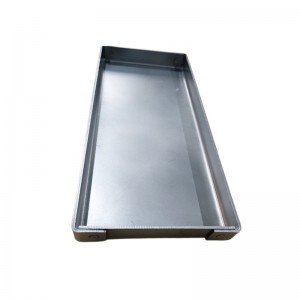

Nkoj Tungsten

Lub nkoj tungsten yog lub thawv ua los ntawm tungsten hlau. Nws yog feem ntau zoo li lub nkoj thiab yog tsim los kom muaj lossis thauj cov ntaub ntawv hauv ntau hom kev siv kub. Tungsten nkoj yog dav siv nyob rau hauv lub tshuab nqus tsev deposition txheej txheem xws li thermal evaporation thiab electron beam evaporation, uas yuav tsum tau meej tswj ntawm cov khoom deposited.

Cov nkoj tungsten yog thawj qhov kev xaiv rau lub tshuab nqus tsev vim lawv qhov siab melting point (3422 ° C), thermal conductivity zoo heev, thiab tiv thaiv thermal shock thiab tshuaj corrosion. Cov khoom no ua rau cov nkoj tungsten zoo tagnrho rau kev tuav thiab evaporating cov ntaub ntawv ntawm qhov kub thiab txias yam tsis muaj deforming lossis reacting nrog cov khoom tso.

Nyob rau hauv lub tshuab nqus tsev deposition txheej txheem, cov khoom yuav tsum tau evaporated yog muab tso rau hauv ib lub nkoj tungsten thiab ces rhuab mus rau qhov xav tau kub siv resistive cua sov los yog electron beam bombardment. Thaum cov khoom ncav cuag qhov kub ntawm evaporation, nws evaporates thiab tsim ib zaj duab xis nyias ntawm cov khoom siv hauv paus, tso cai rau kev tswj xyuas meej ntawm cov txheej txheem deposition thiab cov khoom ntawm cov yeeb yaj kiab.

Tungsten nkoj muaj nyob rau hauv ntau qhov ntau thiab tsawg thiab kev teeb tsa kom haum rau cov txheej txheem sib txawv thiab cov khoom siv. Peb muab evaporation nkoj nyob rau hauv txawv lengths, widths, thicknesses, thiab cov ntaub ntawv, thov hu rau peb kom paub meej.

Tungsten Boat Information

| Cov khoom npe | Tungsten (W) Nkoj |

| Xaiv cov khoom siv | W, Mo, Ta |

| Qhov ntom | 19.3g / cm³ |

| Purity | ≥99.95% |

| Technology | Kub Kub Stamping, Vuam, thiab lwm yam. |

| Daim ntawv thov | Nqus Thermal Evaporation |

Tungsten nkoj Specifications

| Qauv | Thickness (hli) | Dav (mm) | Ntev (mm) |

| #210 | 0.2 | 10 | 100 |

| #215 | 0.2 | 15 | 100 |

| #220 | 0.2 | 20 | 100 |

| #310 | 0.3 | 10 | 100 |

| #315 | 0.3 | 15 | 100 |

| #320 | 0.3 | 20 | 100 |

| #510 | 0.5 | 10 | 100 |

| #515 | 0.5 | 15 | 100 |

| Lus Cim: Ntau qhov tshwj xeeb tuaj yeem kho tau | |||

Daim ntawv thov

Tungsten nkoj yog dav siv nyob rau hauv high-temperature thiab lub tshuab nqus tsev ib puag ncig xws li nqus evaporation thiab cov khoom siv thaum tshav kub kub kho. Lawv yog ib qho ntawm cov cuab yeej tseem ceeb hauv kev npaj cov yeeb yaj kiab nyias thiab cov ntaub ntawv tshawb fawb. Cov hauv qab no yog cov chaw siv ntau yam ntawm tungsten nkoj:

• Nqus evaporation

• Electron beam evaporation

• Cov khoom siv cua sov kho

• Kev tshawb fawb cov ntaub ntawv hlau

•Semiconductor Manufacturing

Peb muab evaporation qhov chaw thiab evaporation cov ntaub ntawv rau PVD txheej & Optical txheej, cov khoom no muaj xws li:

| Electron Beam Crucible Liners | Tungsten Coil rhaub | Tungsten Cathode Filament |

| Thermal Evaporation Crucible | Cov khoom siv evaporation | Nkoj Evaporation |

Tsis muaj cov khoom koj xav tau? Thov hu rau peb, peb yuav daws nws rau koj.

Koj puas xav paub ntau ntxiv txog peb cov khoom?

Tiv tauj peb

Amanda│Tus Thawj Tswj Muag

E-mail: amanda@winnersmetals.com

Xov tooj: 0086 156 1977 8518 (WhatsApp/Wechat)

Yog tias koj xav tau cov ntsiab lus ntxiv thiab tus nqi ntawm peb cov khoom, thov hu rau peb tus neeg muag khoom, nws yuav teb sai li sai tau (feem ntau tsis pub dhau 24 teev), ua tsaug.