Nqus txheej, tseem hu ua nyias zaj duab xis deposition, yog lub tshuab nqus tsev chamber txheej txheem uas siv ib tug heev nyias thiab ruaj khov txheej rau saum npoo ntawm lub substrate los tiv thaiv nws los ntawm lub zog uas yuav txwv tsis pub hnav los yog txo nws cov efficiency.Lub tshuab nqus tsev yog nyias, ntawm 0.25 thiab kaum microns (0.01 txog 0.4 nti) tuab.

Peb hom ntawm lub tshuab nqus tsev vacuum:

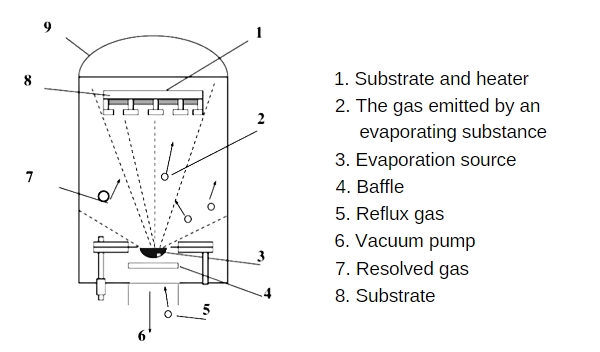

Evaporation txheej

Hauv lub tshuab nqus tsev, lub evaporator yog siv los ua kom sov cov khoom evaporated rau sublimate nws, thiab cov evaporated granular flow yog ncaj qha mus rau lub substrate thiab tso rau nws los ua ib tug khoom zaj duab xis, los yog lub tshuab nqus tsev txheej yog siv los ua kom sov thiab evaporate lub coated. khoom.Peb lub tuam txhab muaj peev xwm muab cov evaporators thiab cua sov cov ntsiab lus, suav nrog ntau lub nkoj ua los ntawm cov hlau refractory xws li tungsten, molybdenum thiab tantalum, nrog rau tungsten xov hlau thiab tungsten strands rau cua sov.

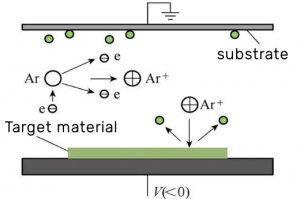

Sputtering txheej

Nyob rau hauv lub tshuab nqus tsev, lub hom phiaj nto yog bombarded nrog high-zog hais, thiab cov bombarded hais yog tso rau ntawm substrate.Feem ntau, cov khoom yuav tsum tau muab tso rau hauv lub phaj-hom khoom, thiab lwm yam, thiab refractory tshuaj xws li tungsten, molybdenum, tantalum, thiab titanium yuav sputtered.Peb lub tuam txhab tuaj yeem muab cov tungsten phaj siab, molybdenum phaj, tantalum phaj, titanium phaj thiab ntau yam khoom siv, uas tuaj yeem siv rau sputtering txheej.

Ion plating

Ion plating yog siv cov pa tawm mus rau ionize cov pa los yog cov khoom evaporated nyob rau hauv lub tshuab nqus tsev thiab tso cov khoom evaporated los yog nws cov reactant rau ntawm lub substrate thaum cov roj ions los yog cov khoom evaporated ions yog bombarded.Ntxiv nrog rau cov hlau tsis muaj hlau, cov txheej txheem ntawm lub tshuab nqus tsev kuj tseem muaj cov hlau tsis muaj hlau, xws li oxides, silicon oxides thiab txhuas oxides.

Yav tom ntej tiam

Nrog rau txoj kev loj hlob ntawm cov kev tshawb fawb niaj hnub thiab thev naus laus zis, lub tshuab nqus tsev txheej tshuab tau siv ntau thiab ntau dua, tsis yog tsuas yog ua lub luag haujlwm tseem ceeb hauv cov neeg siv khoom siv hluav taws xob, kev sib koom ua ke, cov khoom siv kho qhov muag optoelectronic thiab lwm yam kev lag luam, tab sis kuj hauv cov khoom siv kho mob, aerospace, hnub ci zog, plastics, ntim, textile, machinery, anti-country, kev tsim kho thiab lwm yam kev lag luam.

BAOJI Winners Hlau tuaj yeem muab crucible rau evaporation xws li tungsten, molybdenum, tantalum, thiab lwm yam., evaporation nkoj, sputtering phiaj khoom (tungsten, molybdenum, tantalum, Niobium, titanium, thiab lwm yam), electron phom tungsten hlau, tungsten cua sov thiab lwm yam. txheej consumables, accessories.thov hu rau peb kom paub ntau ntxiv (Whatsapp + 86 156 1977 8518).

Post lub sij hawm: Aug-02-2022