Sputtering phiaj Titanium 99.7

Product Description

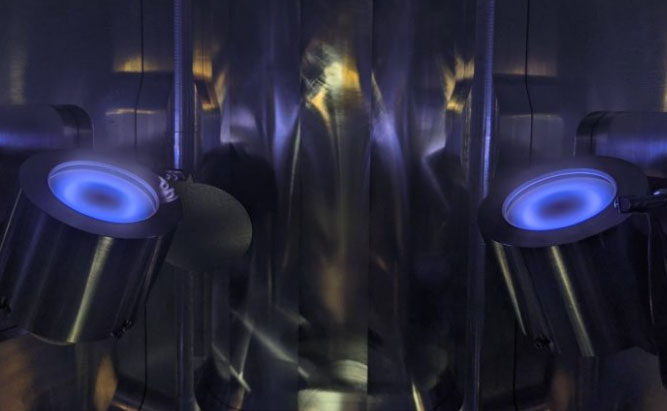

Magnetron Sputtering ua haujlwm li cas?

Magnetron sputtering yog lub cev vapor deposition (PVD) txoj kev, ib chav kawm ntawm lub tshuab nqus tsev deposition txheej txheem los ua nyias films thiab coatings.

Lub npe "magnetron sputtering" tshwm sim los ntawm kev siv magnetic teb los tswj cov nqi ion particles tus cwj pwm hauv cov txheej txheem magnetron sputter deposition.Cov txheej txheem yuav tsum muaj lub tshuab nqus tsev siab los tsim kom muaj qhov chaw qis rau sputtering.Cov roj uas muaj cov ntshav, feem ntau yog argon gas, nkag mus rau hauv chav ua ntej.

Lub siab tsis zoo hluav taws xob yog siv nruab nrab ntawm cathode thiab anode los pib lub ionisation ntawm cov roj inert.Qhov zoo argon ions los ntawm cov ntshav plasma tsoo nrog cov khoom siv tsis zoo.Txhua qhov kev sib tsoo ntawm cov khoom siv hluav taws xob siab tuaj yeem ua rau cov atoms los ntawm lub hom phiaj ntawm qhov chaw tawm mus rau hauv lub tshuab nqus tsev thiab txav mus rau qhov chaw ntawm lub substrate.

Ib qho chaw sib nqus muaj zog ua rau cov ntshav plasma siab ceev los ntawm kev kaw cov electrons nyob ze ntawm lub hom phiaj saum npoo, nce tus nqi ntawm deposition thiab tiv thaiv kev puas tsuaj rau lub substrate los ntawm ion bombardment.Cov ntaub ntawv feem ntau tuaj yeem ua lub hom phiaj rau cov txheej txheem sputtering txij li lub tshuab magnetron sputtering tsis xav tau melting lossis evaporation ntawm cov khoom siv.

Khoom Parameters

| Cov khoom npe | Ntshiab titanium phiaj |

| Qib | Gr1 |

| Purity | Ntau tshaj 99.7% |

| Qhov ntom | 4.5g / cm3 |

| MOQ | 5 qab |

| Kub muag loj | Φ95 * 40mm Φ98 * 45 hli Φ100 * 40 hli Φ128 * 45 hli |

| Daim ntawv thov | Txheej rau PVD tshuab |

| Tshuag loj | Φ98 * 45 hli Φ100 * 40 hli |

| Lwm Cov Hom Phiaj muaj | Molybdenum (Mo) Chrome (Cr) TiAl Tooj liab (Cu) Zirconium (Zr) |

Daim ntawv thov

■Txheej integrated circuits.

■Nto vaj huam sib luag qhia txog cov vaj huam sib luag tiaj tus thiab lwm yam khoom.

■Kho kom zoo nkauj thiab iav txheej, thiab lwm yam.

Yam khoom twg peb tuaj yeem tsim tau

■High-purity titanium tiaj hom phiaj (99.9%, 99.95%, 99.99%)

■Standard threaded kev twb kev txuas rau installation yooj yim (M90, M80)

■Kev ywj pheej ntau lawm, tus nqi pheej yig (zoo controllable)

Cov ntaub ntawv xaj

Kev nug thiab kev txiav txim yuav tsum muaj cov ntaub ntawv hauv qab no:

■ Txoj kab uas hla, Qhov siab (xws li Φ100 * 40mm).

■ Xov loj (xws li M90 * 2mm).

■ Ntau.

■ Purity xav tau.